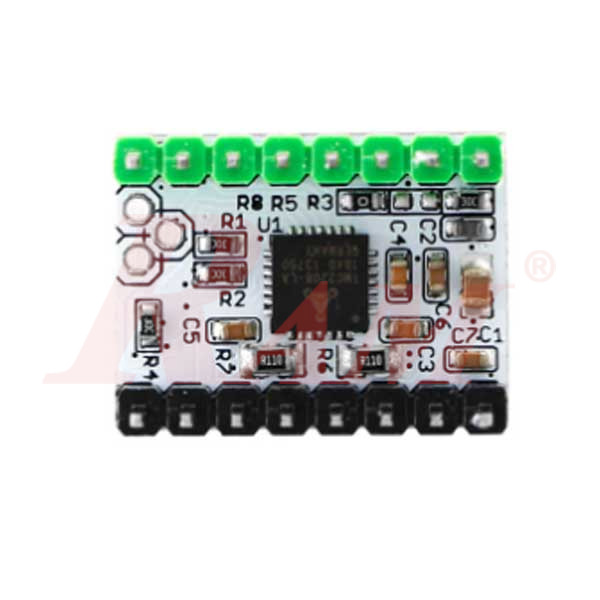

TMC2208 V2.0 Stepper Motor Driver 1.4A - MKS

Internal Reference:

KIT.TMC2208.DRIVER

3D Printer Parts Stepstick TMC2208 Super Quiet Stepper Motor Driver With New Heatsinks Replace Ramps 1.4, 1.5 & 1.6 Reprap Board

- Manufacturer: MakerBase

- Model No.: MKS TMC2208 V2.0

- Control Interface(s):

- Step/Dir

- UART

- Native Microsteps: Up to 1/16

- MicroPlyer Microsteps: Up to 1/256

- Logic Voltage (VIO): 3V to 5V

- Motor Supply Voltage (VM): 4.75V to 36V

- Rated Motor Phase Current: 1.4A RMS | 2A Peak

- Internal Voltage Regulator: Enabled

- RDSon: ≤0.3Ω

- TMC Features:

- MicroPlyer

- SpreadCycle

- CoolStep

- StealthChop2

- DcStep

- Weight: ±2g

- Dimensions: 15 x 20mm

THE KEY FEATURES OF TMC2208 V2.0 STEPPER MOTORS DRIVERS:

When looking at the vast array of different stepper motor drivers available to Makers, it’s easy to get confused at which would actually cater to your application best. Fortunately, though, we’ve taken the time to single out the key features that make each of our stepper drivers so great, so that you can more easily identify which drivers you’re eager to use, and which can offer the benefits that matter most to you. So, with that being said, let’s take a closer look at precisely what makes these TMC2208 stepper drivers so amazing.

UART Interfacing:

While many of the stepper motor drivers from the past few years have been quite complex to set up, due to the fact that they weren’t originally designed for 3D Printing, one of the more recent improvements to the industry is in the way we interface with stepper drivers. This is why we’re so eager about the UART Interfacing that these TMC2208 drivers offer, as it allows for far more control than the old Step/Dir method, allowing users to control all of the control lines (EN / DIAG / INDEX / MS1 / MS2 / Analog Current / VRef) via a single line of code.

Additionally, UART Interfacing also allows for quick and easy configuration without having to rewire pins, with the actual software being able to define motor current, Microsteps, Chopper Modes and more – all while sitting at your computer or laptop. Additionally, as if the above wasn’t enough, UART Interfacing also greatly reduces current consumption when the motors are in standby mode, helping to extend the lifespan of the motors and save electricity at the same time.

StealthChop2:

If you already know what the original StealthChop is, and the awesome benefits that it offers, then you will hopefully be just as excited as we are with the new StealthChop2, which is similar to original, but integrates a current pre-regulator to avoid overcompensation of step prediction, while allowing for more torque during acceleration phases. And while this may sound complicated at first, what it translates to is fewer missed steps or overshot steps, as well as a higher level of power even when motors are caught in an odd rotor position. This means more reliability and more predictability for your motors, and of course the awesome near-silent operations that both StealthChop and SpreadCycle are well-known for.

Download